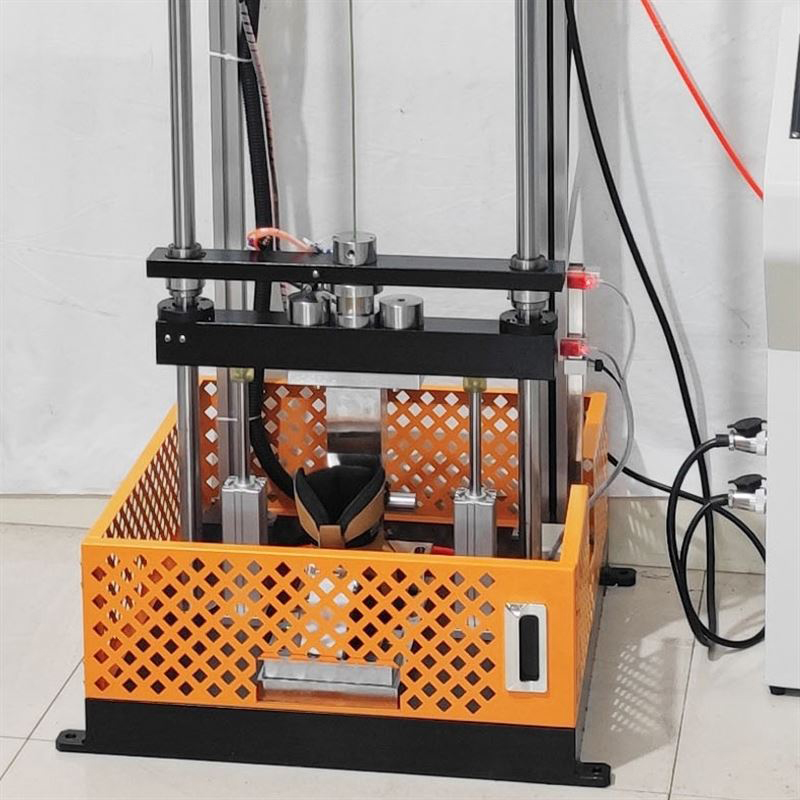

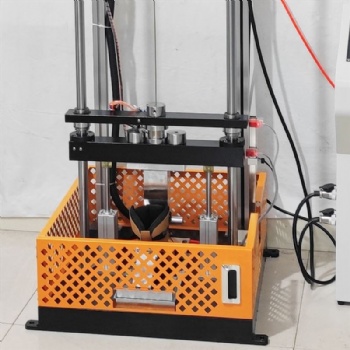

WT-6026 safety shoe impact resistance tester

WT-6026 safety shoe impact resistance tester

WT-6026 safety shoe impact resistance tester

![]() safety shoe impact resistance tester.pdf

safety shoe impact resistance tester.pdf

1. Introductions

The safety shoe impact resistance testing machine is used to test the impact and impact resistance performance of materials such as safety shoes or protective shoes, such as toe caps, bare steel toe caps, plastic toe caps, aluminum steel toe caps, etc.

2. Relative test methods

ANSI Z41 Personal Protection - Protective Footwear

BS EN 344-1 safety,protective and occupational footwear for professional use——part 1:requirements and test methods

BS EN 344-2 safety,protective and occupational footwear for professional use——part 2:additional requirements and test methods

CSA Z195 protective footwear

ISO 20344 personal protective equipment——test methods for footwear

LD 50-94 Protective toe safety shoes (boots)

ASTM F2412 standard test methods for foot protection

EN12568 foot and leg protectors——requirements and test methods for toecaps and penetration resistant inserts

CNS 6863 protective footwears

GB4014 leather safety shoes

GB/T 20991/ ISO 20344 personal protective equipment——test methods for footwear

GB21148 / ISO 20345 personal protective equipment——safety footwear

JIS T8101 safety shoes

3.specifications

No. | Item | Spec. |

1 | Effective test height | 1200mm |

2 | Impact hammer | (20±0.2)kg for EN,GB methods and (22±0.2)kg for CSA,USA methods |

3 | Speed meter | Digital display speed |

4 | Impact mode | Free falling |

5 | Hammer release mode | Electromagnetic release |

6 | Prevent secondary impact | Yes |

7 | Secondary induction switch | Photoelectric induction, precise and sensitive |

8 | Dimension | 690x650x1880mm |

9 | Weight | 118kg |

10 | Voltage | AC220V |

4. features

l Body surface treatment: Using DuPont powder from the United States and electrostatic spray painting technology, it is cured at high temperature of 200 ℃ to ensure long-lasting color fastness.

l Mechanical components are composed of non-corrosive structures and stainless steel materials

l Precision motor drive, accurate control, smooth operation, low noise

l One click fully automatic testing, easy and convenient to operate

l Imported high-precision bearings, low friction and high precision

l Dual cylinder anti secondary impact

l Height and energy can be customized, with speed display and automatic positioning adjustment function

l Supporting various standard testing methods

l Add protective nets to the body to prevent accidental injury to workers

l Laser induction switch with high energy accuracy and sensitive induction

l Independent control console to prevent vibration

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- all testing machine and equipment

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

- test fixtures

- torsion tester

- cupping testing machine

- friction and wear tester

Contact Us

- +86-18615632092

- sophie@jnwtbte.com

- +86-18615632092

售前客服

售前客服