Computerized glass cover Bending Tester

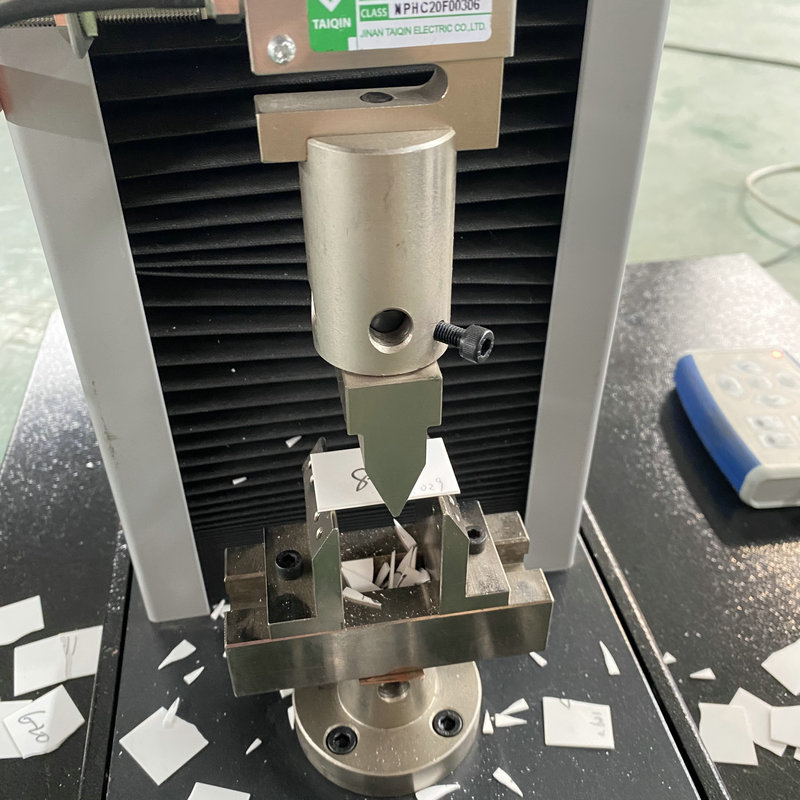

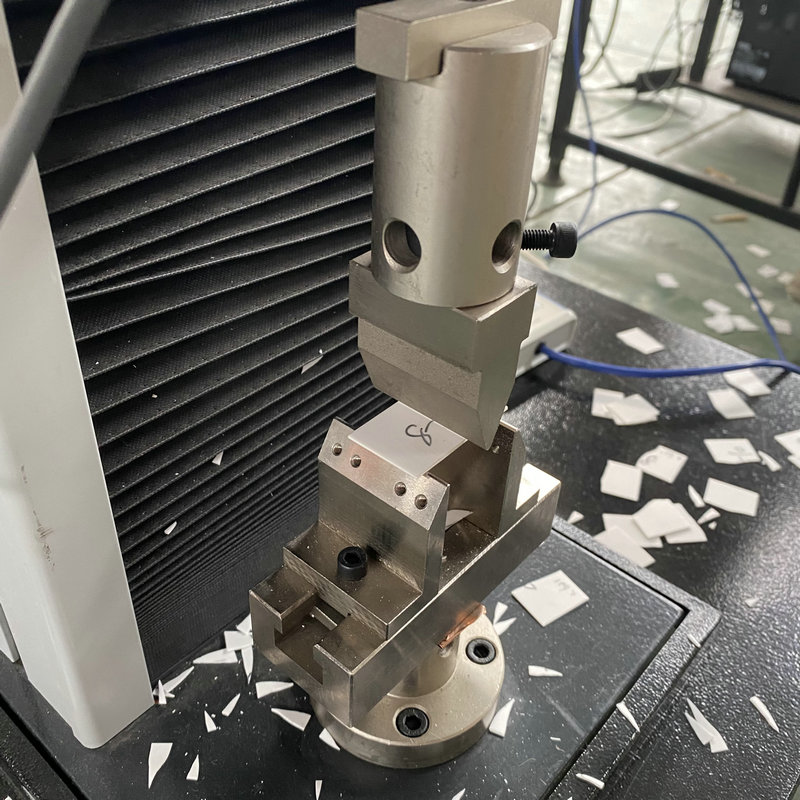

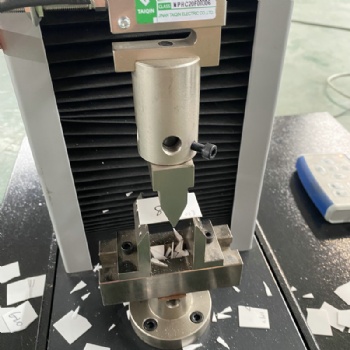

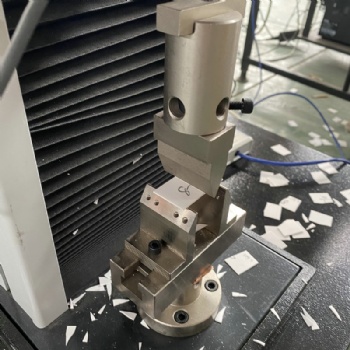

Microcomputer-controlled glass cover bending testing machine can be used to test the three-point bending strength and four-point bending strength of materials such as mobile phone cover, tablet computer, liquid crystal glass, touch glass, photovoltaic glass and plastic.

Computerized glass cover Bending Tester

1 Introduction

Microcomputer-controlled glass cover bending testing machine can be used to test the three-point bending strength and four-point bending strength of materials such as mobile phone cover, tablet computer, liquid crystal glass, touch glass, photovoltaic glass and plastic. The microcomputer-controlled glass cover bending testing machine system adopts microcomputer closed-loop control, has a wide and accurate loading speed and force measurement range, and has high precision and sensitivity for the measurement and control of load and displacement.

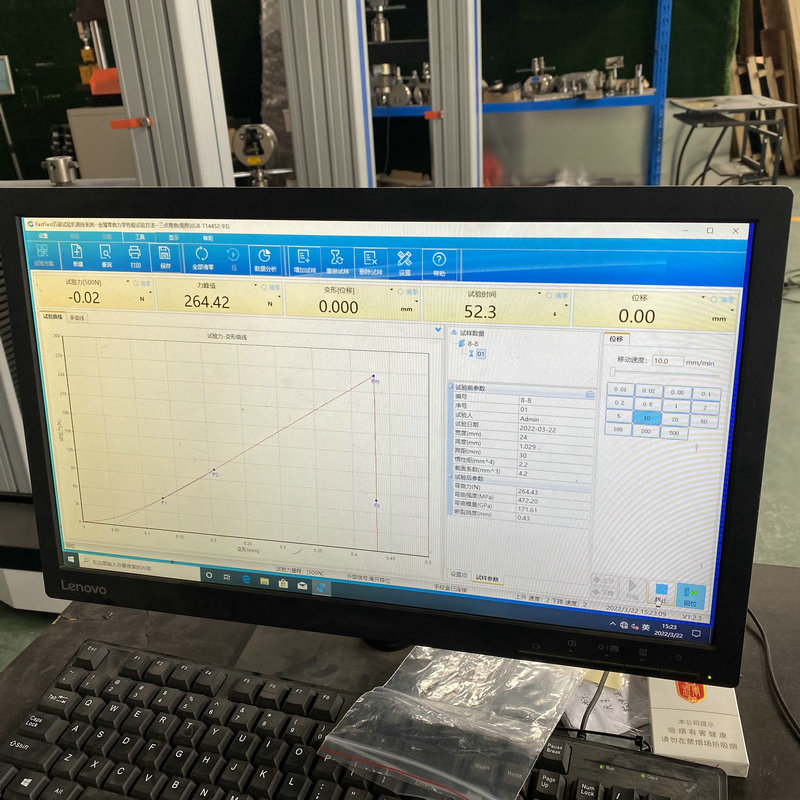

2.relative test method for glass cover bending test

JJG/T676 test method for flexure of glass material

JC/T 2130 cover glass for windows of mobile electronic devices

GB/T 9341 plastics – determination of flexural properties

ISO 178 plastics – determination of flexural properties

BS EN 1288-3 determination of bending strength of glass – part 3: test with specimen supported at two points ( four point bending)

GB/T 1449 fibre-reinforced plastic composites – determination of flexural properties

ISO 14125 fibre-reinforced plastic composites – determination of flexural properties

ASTM D6109 standard test method for flexural properties of unreinforced and reinforced plastic lumber and related products

3. Relative manufacturing and calibrating test method for cover glass bending testing machine

GB/T2611 general requirements for testing machines

GB/T16491 electronic universal testing machine

GB/T16825.1 verification of static uniaxial testing machines --- part 1: tension / compression testing machines --- verification and calibration of the force measuring system

ISO7500-1 metallic materials--- verification of static uniaxial testing machine --- part 1: tension / compression testing machines --- verification and calibration of the force measuring system

ASTM E4 standard practice for force verification of testing machines

EN 10002-2 tensile testing of metallic materials --- part 2: verification of the force measuring system of the tensile testing machine

4. working conditions of testing machine

4.1 The room temperature is 10-35℃.

4.2 Relative humidity≤80%.

4.3 There is no vibration around, no corrosive medium, and no strong magnetic field interference.

4.4 The power supply voltage fluctuation should not exceed 10% of the rated voltage.

4.5 Install it horizontally on a solid foundation with a level of 0.2/1000.

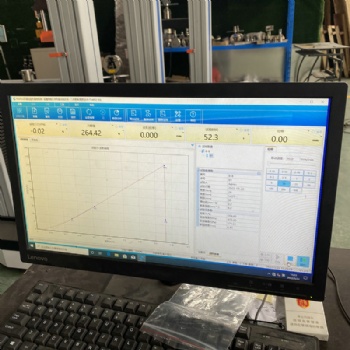

5. features of test software

5.1. Automatic stop: After the sample is broken, the moving beam stops automatically;

5.2. Condition storage: The test control data and sample conditions can be made into modules, which facilitates the batch test;

5.3. Automatic speed change: The speed of the moving beam during the test can be changed automatically according to the preset program or manually;

5.4. Automatic calibration: the system can automatically realize the calibration of the indication accuracy;

5.5. Automatic save: After the test is over, the test data and curves are automatically saved;

5.6. Process realization: the test process, measurement, display and analysis are all completed by the microcomputer;

5.7. Batch test: for samples with the same parameters, it can be completed in sequence after one setting

5.8. Test software: WINDOWS interface, menu prompt, mouse operation;

5.9. Display mode: data and curves are dynamically displayed with the test process;

5.10. Curve traversal: After the test is completed, the curve can be re-analyzed, and the test data corresponding to any point on the curve can be found with the mouse;

5.11. Curve selection: Stress-strain, force-displacement, force-time, displacement-time and other curves can be selected for display and printing as required;

12. Test report: The report can be prepared and printed according to the format required by the user;

5.13. Limit protection: with two levels of program control and mechanical limit protection;

5.14. Overload protection: when the load exceeds 3-5% of the maximum value of each gear, it will automatically stop;

5.15. The test results are obtained in two modes, automatic and manual, and reports are automatically formed, which makes the data analysis process simple.

6. specification of cover glass bending testing machine

No | Item | Specification |

1 | Force capacity | 100N,200N,500N,1000N,2000N,5000N |

2 | Force measuring range | 0.4%-100%FS |

3 | Error of force value | Less than ±1% of set value |

4 | Resolution of test force | 1/500000 |

5 | Displacement resolution | 0.0025mm |

6 | Accuracy of elongation measuring | ±0.5% |

7 | Crossbeam speed range | 0.05-500mm/min |

8 | Precision of displacement speed control | ±1%(0.01-10mm/min); ±0.5%(10-500mm/min) |

9 | Accuracy of constant force, constant displacement, displacement elongation control | When set value is less than 10%FS,error is less than ±1.0% of set value When set value is more than 10%FS,error is less than ±0.1% of set value |

10 | Accuracy of deformation control | When set value is less than 0.05%FS,error is less than ±2.0% of set value When set value is more than 0.05%FS,error is less than ±0.5% of set value |

11 | Distance between tensile grips | 650mm |

12 | Voltage | Single phase,220V±10%,50Hz |

13 | Dimension | 520x480x1550mm |

14 | Weight | 80kg |

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- utm

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服