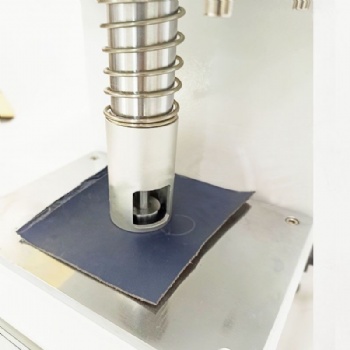

WT-6061 rub rotary friction fading color fastness testing machine

WT-6061 rub rotary friction fading color fastness testing machine

![]() WT-6061 rub rotary friction fading color fastness testing machine.pdf

WT-6061 rub rotary friction fading color fastness testing machine.pdf

The rub rotary friction fading color fastness testing machine is used to evaluate the degree of damage and surface color transfer of materials after dry or wet friction. It is suitable for shoe upper materials such as leather, plastic, and textiles. The testing principle of the rub rotary friction fading color fastness testing machine is to use a circular wool felt (dry or wet) to press the sample with a fixed weight. When the wool felt rotates, it rubs the sample a certain number of times, and then evaluates the degree of color change of the sample. It can also be used to evaluate the friction fastness of the font printed on the surface of the shoe material.

2. Relative test methods

SATRA TM8, QB/T2882, QB/T5243

3.specifications

Item | Spec. | |

1 | Specimen size | 60x60mm or φ60mm |

2 | Rotating speed | 150±5RPM |

3 | Round plate size | φ60mm, thickness 12mm |

4 | Wool felt size | Outside diameter 25±1mm, inside diameter 3±0.5mm |

5 | Force loaded | 24.5±0.5N or 7.1±0.2N |

6 | Dimension | 300x380x500mm |

7 | Weight | 40kg |

4. features

4.1 Surface treatment of the body: Using DuPont powder from the United States and electrostatic spray painting technology, it is cured at high temperature of 200 ℃ to ensure long-lasting color fastness.

4.2 Mechanical components are composed of non corrosive structural aluminum and stainless steel materials;

4.3 LED-SLD806 integrated display control box, menu style operation mode;

4.4 Precision drive motor, running smoothly and with low noise;

4.5 Detachable weight, manually pressed ring to fix the sample, standard horizontal table for friction test

rubber rotary friction tester, color fastness tester, fading color fastness testing, color fastness to rubbing, rotational rubbing fastness, friction fading color tester, textile color fastness machine, fabric rubbing fastness tester, iso 105-x12

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- all testing machine and equipment

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

- test fixtures

- torsion tester

- cupping testing machine

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服