News

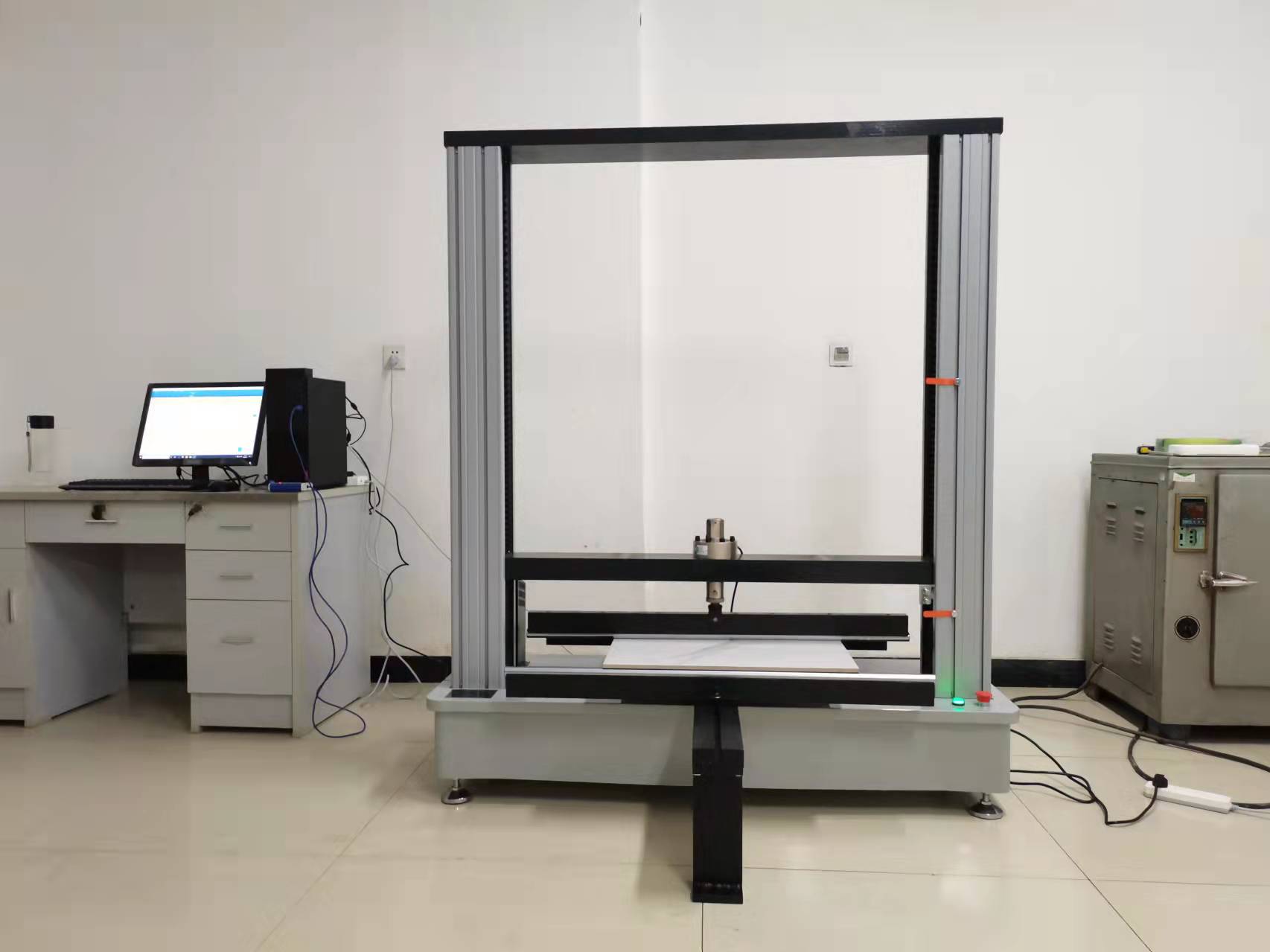

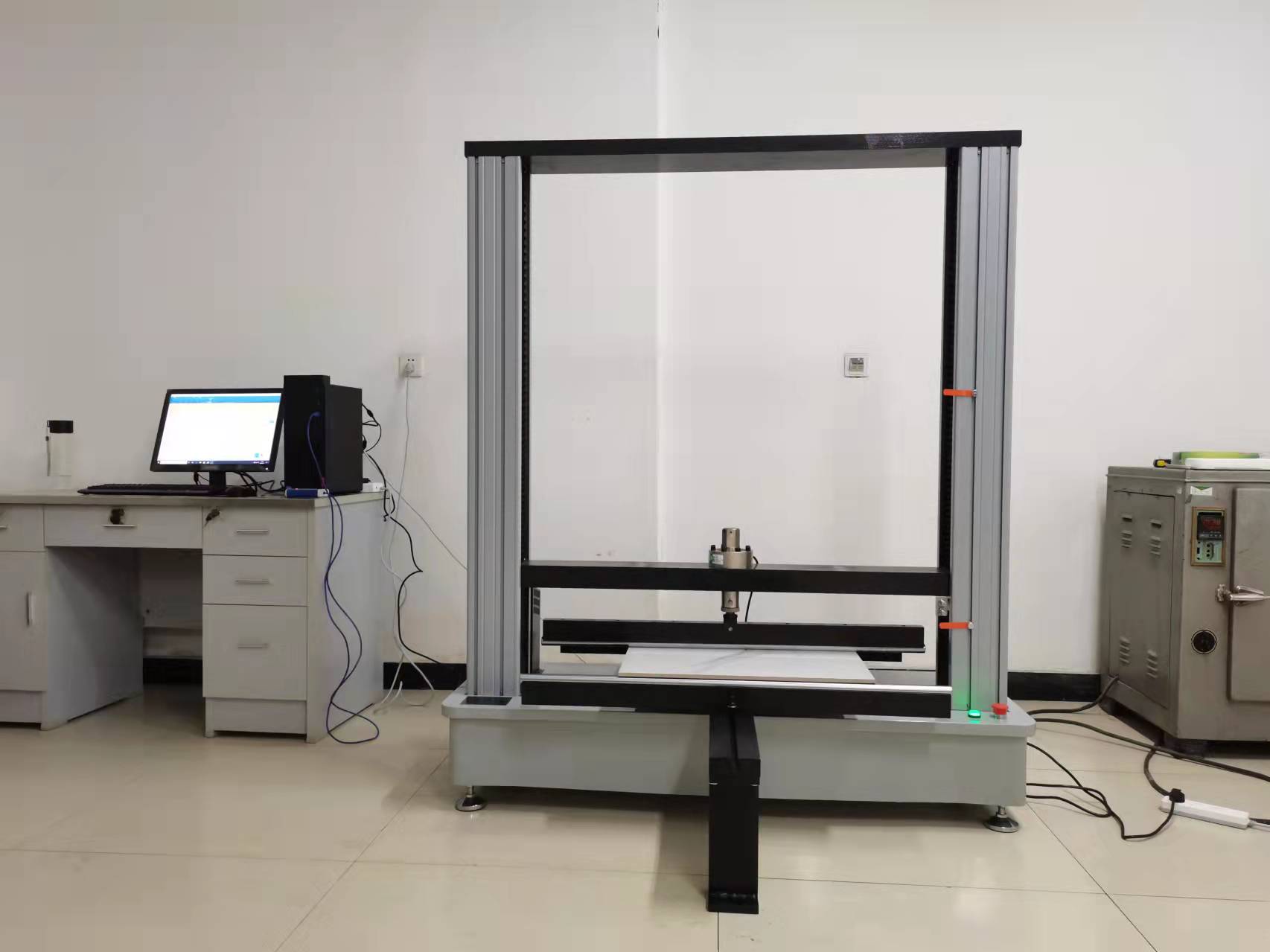

Computerized electronic universal tester for glass bending test

Computerized electronic universal testing machine for glass bending test

1. Introduction of glass

Glass is an amorphous inorganic non-metallic material, which is generally made of a variety of inorganic minerals as the main raw material, and a small amount of auxiliary raw materials are added. Its main components are silicon dioxide and other oxides, which are widely used in buildings to block wind and light, and belong to a mixture. There are also colored glass mixed with oxides or salts of certain metals to show color, and tempered glass prepared by physical or chemical methods, and sometimes some transparent plastics (such as polymethyl methacrylate) Also known as plexiglass. The main uses of glass are architectural glass, automotive glass and photovoltaic glass.

2. relative test method of glass bending and flexural test

GB/T 17841 heat strengthened glass

GB/T 34328 light weight thermally strengthened glass

EN 1288-3 glass in building – determination of bending strength of glass --- part 3: test with specimen supported at two points (four point bending)

JC/T 676 test method for flexure of glass material

GB 15763.4 safety glazing materials in building --- part 4: heat soaked thermally tempered glass

EN 14179-1 glass in building – heat soaked thermally toughened soda lime silicate safety glass --- part 1: definition and description

3. features of 3 and 4 point bending and flexural testing machine for glass

3.1. Using AC servo motor and AC servo speed control system to control the test process, the control accuracy and quality are greatly improved, stable, efficient, low noise (basically no noise at low speed) and the control speed range is greatly widened (0.05-500mm/min) ), which is not only conducive to low-speed testing of conventional materials (metal, cement, concrete, etc.), but also conducive to high-speed testing of non-metallic materials (rubber, etc.), and can also be used to quickly adjust the test space at no-load, saving auxiliary test time. This test speed meets the requirements for most metal and non-metallic materials.

3.2. The deceleration mechanism composed of synchronous toothed belt and precision ball screw pair makes the structure more concise and bright, and the transmission efficiency is greatly improved, more coordinated.

3.3. The double-space structure with independent tension and compression is adopted, which is convenient to operate and avoids the troublesomeness of changing different test accessories when tension and compression are in the same space.

3.4. Sensors of different specifications can be configured according to requirements, which greatly widens the test range and meets the measurement requirements of different test loads.

3.5. The main engine adopts a full-spray plastic shell, which is elegant and beautiful in shape.

3.6. Using advanced control technology, it has three closed-loop control modes of stress, strain and displacement. Each control loop can be automatically switched, and can achieve a smooth transition without impact when switching between modes, and can display the test force, peak value and displacement, speed, test status, test curve, etc.

3.7. It can control and maintain the rate of test force, deformation and displacement.

3.8. It can realize the fast/slow lifting and lowering adjustment of the beam when the sample is clamped, and the operation is flexible and can be switched at will.

3.9. It has the function of returning to the initial position after the test, which is efficient and fast.

3.10. It has perfect limit protection function, overload, overcurrent protection, automatic shutdown of test break and other functions, which is reliable and safe.

3.11. Self-built powerful test database, test data can be saved, queried and called at any time.

3.12. Provide a variety of report printing interfaces, users can edit reports in any format according to their needs, and print them out;

3.13. The whole control system has high cost performance and high reliability.

3.14. Carry out tensile tests on materials according to national standards or standards provided by users, count and process test data, and then output and print various required test curves and test reports. Load-time, load-displacement, and displacement - Time, deformation-time and other test curves are displayed during test. Test curves can be enlarged, compared, and traversed, and the test process is monitored, very smart and convenient.

3.15. Provide professional users with "Standard Addition Program Editor" software, users can flexibly add required standards according to actual needs;

3.16. The test software under the Windows platform has strong data and graphics processing functions, can print out complete test reports and test curves in real time, and can reserve data interfaces to directly connect to the comprehensive information management network of the enterprise (laboratory). It can also be customized according to the specific situation of the user's local area network.

our products including electronic universal testing machine,hydraulic universal testing machine,impact testing machine,compression testing machine,horizontal tensile testing machine,manhole cover testing machine,pellet compression testing machine,bending

testing machine,wood based panel testing machine,thermainsulating

materials testing machine,high and low temperating testing

machine,ceramic tiles 3 and 4 point bending and flexural testing

machine,steel strand tensile testing machine,tensile stress relaxation

testing machine,spring tensile and compression testing machine,glass

bending testing machine,welcome consulting

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服